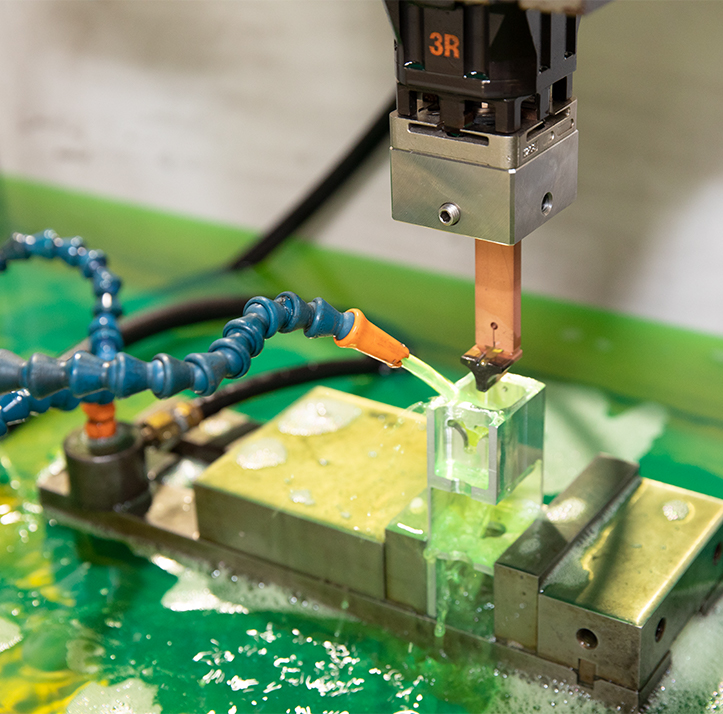

Sinker EDM, also known as ram EDM or plunge EDM, is a process that uses a shaped electrode to erode material from the workpiece. In this process, the electrode is immersed in a dielectric fluid and positioned close to the workpiece, while a spark discharge is generated between the electrode and the workpiece to erode the material. Sinker EDM is commonly used for producing deep cavities, small holes, and complex shapes such as hexagons, circles, and many others in hard and brittle materials such as ceramics and carbides.

Sinker Electrical Discharge Machining (Sinker EDM) is a non-traditional machining process that uses electrical discharge sparks to erode material from a workpiece. Here is a summary of the advantages, and common applications of Sinker EDM.

High precision: Sinker EDM can achieve very precise cuts, making it ideal for applications that require tight tolerances and complex shapes.

Sinker EDM is a non-contact process, which eliminates the risk of tool breakage and reduces the chance of workpiece damage.

Sinker EDM can cut through a wide range of materials, including hardened steel, titanium, and other exotic alloys.

Sinker EDM can produce parts with a very smooth surface finish, even in materials that are difficult to machine using traditional methods.

Sinker EDM is commonly used in industries such as aerospace, automotive, and medical, where high precision and accuracy are essential. Some common applications of Sinker EDM include the production of molds, dies, and tools, as well as the fabrication of intricate parts for the aerospace and medical industries.

Overall, Sinker EDM is a versatile and precise machining process that can produce complex parts with high accuracy and good surface finish.

EDM can cut materials such as:

1. Metals: EDM can cut a variety of metals, including steel, aluminum, titanium, copper, and brass.

2. Alloys: EDM can cut alloys such as stainless steel, tool steel, and nickel-based alloys.

3. Exotic metals: EDM can cut exotic metals such as tungsten, molybdenum, and tantalum.

4. Conductive ceramics: EDM can also cut certain types of ceramics, such as silicon nitride and aluminum oxide, that have high electrical conductivity.

It is important to note that the quality and speed of the EDM process may vary depending on the material being cut. The type of material can affect the machining parameters, such as the cutting speed and electrode material wear.

Submit your 3D (STP,IGS) and technical drawing (DWG, DXF, PDF) for your project.

Our team evaluates the drawing and will provide you with a proposal.

Place your order

Receive parts according to SOW.

Punik EDM, is a privately owned company established in 2000, headquartered in Montreal, Quebec. With decades of manufacturing experience, our team specializes in Wire, Sinker, and Drill EDM to provide exceptional service to our clients.

Links

Contact Us

Phone Number

514-332-9799

Email:

info@punikedm.com

@PunikEDM 2024 . All rights reserved